viewtopic.php?f=11&t=24053&start=45

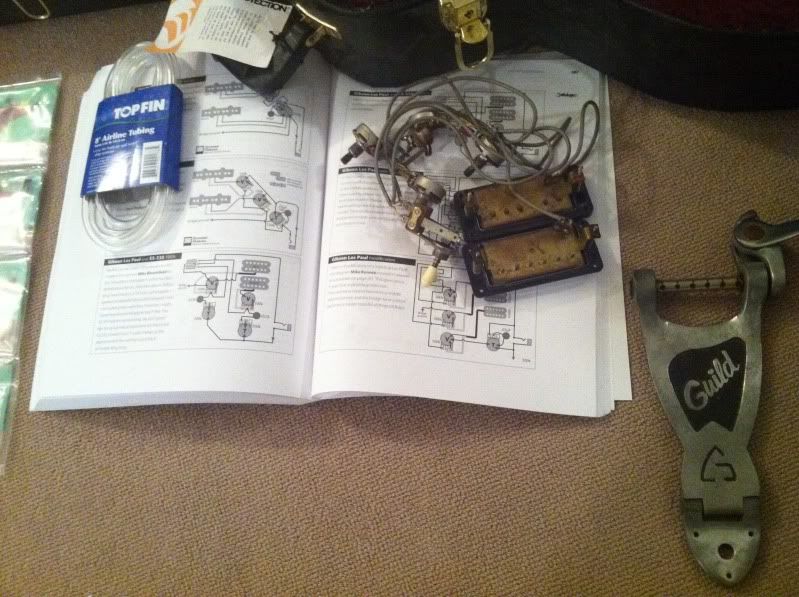

That thread gave me a bit of hope that I could make this happen. given, I solder like i have two left feet on my wrists, and Dan Erlewine's book on guitar repair is the only resource I have other than the thread above to actually know what's what for wiring and such. But what the heck.

I sourced as much as I could think of before the guitar got here, and once the guitar got here, I figured out more that I needed. Still need a spring for the Bigsby, knurled nut for the selector switch, and the correct pickup adjustment screws for the bridge pickup, and mounting screws for the bridge pickup ring.

I found out that the bridge studs are sized for a nashville bridge. YUK. Really considering pulling those studs since they aren't original anyhow, and sourcing a decent Bigsby bridge. Either that, or see if Tru-Arc makes a bar bridge that can sit on nashville studs.

i can't make head or tails on how these locking grover rotomatics are supposed to work, so i think i'll source some old nickel grovers and call it a day. the pickguard l-shaped mounting bracket is not here either, i'll have to source something that'll work.

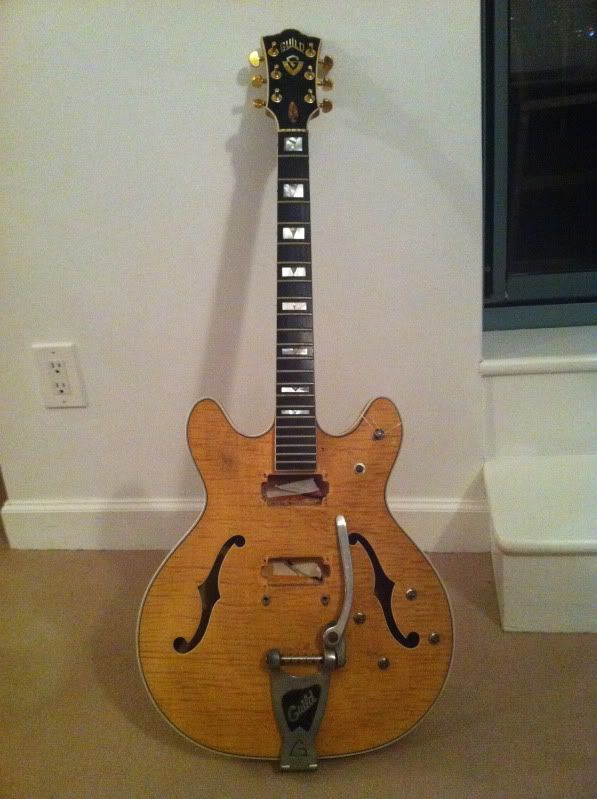

how come i seem a bit nonchalant about getting the perfect parts? because i found out that the neck pickup pocket has been routed on the south wall, probably an attempt to fit a large humbucker in there. gross thing is that once you mount the mini HB-1 in there, even with the ring you see the ugly uneven route. kinda woulda been a dealbreaker if i knew, but hey since it's here and i already put in a evening (or morning, it's 3 AM here now) putting together the Starfire will all given and bought parts, I'll just see it through and have this be my beater.

Speaking of beat, the finish isn't worn - it feels like it was stripped. The neck finish too, like it's raw wood. Only some finish left on the back hints at either a halted refin attempt or maybe the amber was the undercoat spray for the original factory sunburst. Again, not really worth paying for a refin since the body's been routed.

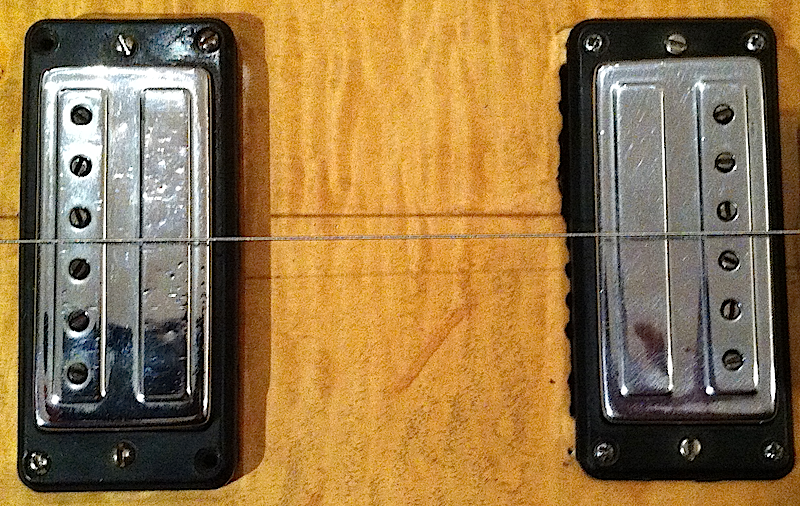

So there you go, probably another hundred or so bucks to get this thing into playing shape. The frets are like fretless wonders, jumbo and flat. I wonder how they'll do, no way to know until i string it up. Well there's a bonus, which is an original '67 Starfire IV harness - pots, switch, jack, all wired up to those HB-1s. I desoldered the pickups and put them on the VI's harness. Off to tap test it now at least.

That thread gave me a bit of hope that I could make this happen. given, I solder like i have two left feet on my wrists, and Dan Erlewine's book on guitar repair is the only resource I have other than the thread above to actually know what's what for wiring and such. But what the heck.

I sourced as much as I could think of before the guitar got here, and once the guitar got here, I figured out more that I needed. Still need a spring for the Bigsby, knurled nut for the selector switch, and the correct pickup adjustment screws for the bridge pickup, and mounting screws for the bridge pickup ring.

I found out that the bridge studs are sized for a nashville bridge. YUK. Really considering pulling those studs since they aren't original anyhow, and sourcing a decent Bigsby bridge. Either that, or see if Tru-Arc makes a bar bridge that can sit on nashville studs.

i can't make head or tails on how these locking grover rotomatics are supposed to work, so i think i'll source some old nickel grovers and call it a day. the pickguard l-shaped mounting bracket is not here either, i'll have to source something that'll work.

how come i seem a bit nonchalant about getting the perfect parts? because i found out that the neck pickup pocket has been routed on the south wall, probably an attempt to fit a large humbucker in there. gross thing is that once you mount the mini HB-1 in there, even with the ring you see the ugly uneven route. kinda woulda been a dealbreaker if i knew, but hey since it's here and i already put in a evening (or morning, it's 3 AM here now) putting together the Starfire will all given and bought parts, I'll just see it through and have this be my beater.

Speaking of beat, the finish isn't worn - it feels like it was stripped. The neck finish too, like it's raw wood. Only some finish left on the back hints at either a halted refin attempt or maybe the amber was the undercoat spray for the original factory sunburst. Again, not really worth paying for a refin since the body's been routed.

So there you go, probably another hundred or so bucks to get this thing into playing shape. The frets are like fretless wonders, jumbo and flat. I wonder how they'll do, no way to know until i string it up. Well there's a bonus, which is an original '67 Starfire IV harness - pots, switch, jack, all wired up to those HB-1s. I desoldered the pickups and put them on the VI's harness. Off to tap test it now at least.