You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AHG octave mando build

- Thread starter AcornHouse

- Start date

AcornHouse

Venerated Member

Cutting nut slots needs to be right from the start. Which means careful layout and double (triple?) checking before anything cuts in.

Then I used a couple of saws to make the initial cuts, with my vintage English saw getting to where I can start filing. That way the files have a groove to seat in and don't skate all over the place.

Finally the nut files get the slots to thickness and preliminary depth. I also angle them towards the tuner posts now.

Then I used a couple of saws to make the initial cuts, with my vintage English saw getting to where I can start filing. That way the files have a groove to seat in and don't skate all over the place.

Finally the nut files get the slots to thickness and preliminary depth. I also angle them towards the tuner posts now.

AcornHouse

Venerated Member

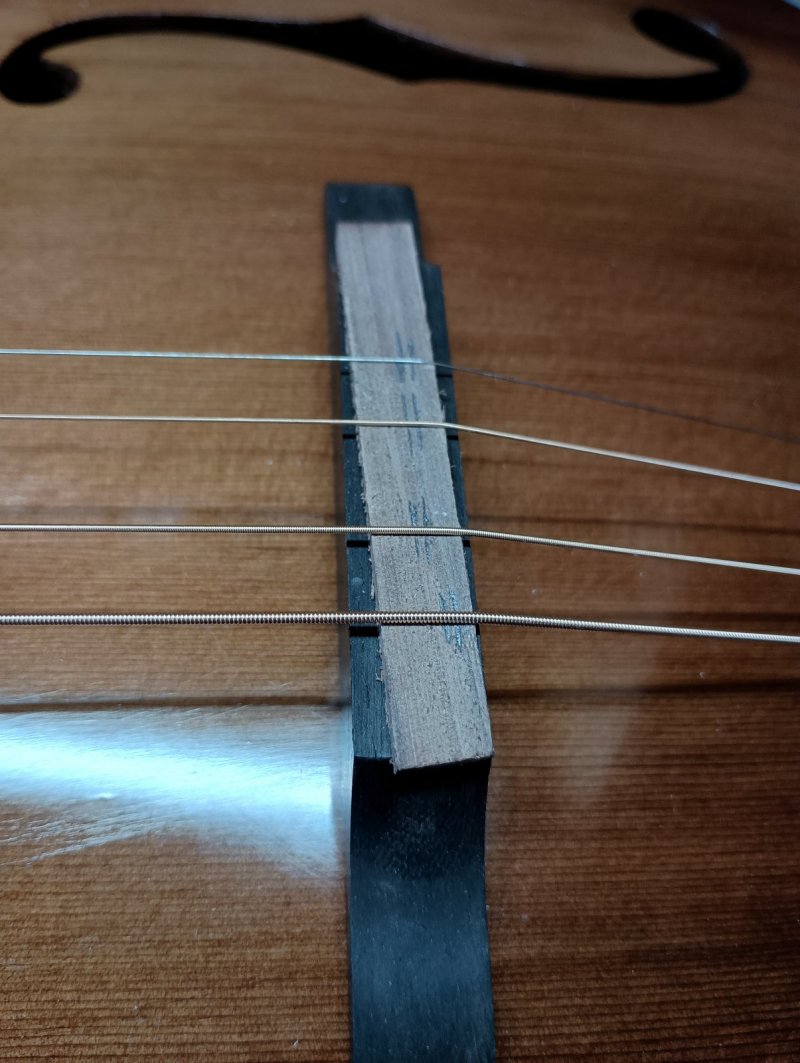

My method for determining the intonation points on the saddle involves glueing a thin piece of, in this case, walnut to the bridge with just a small dab of super glue. Stringing up the 4 different strings (no need to put on all 8 since the pairs are tuned in the same octave); bringing them to pitch. Then, using a small piece of wire, finding where the saddle will need to be.

You a slick builder, Chris--and super creative!!My method for determining the intonation points on the saddle involves glueing a thin piece of, in this case, walnut to the bridge with just a small dab of super glue. Stringing up the 4 different strings (no need to put on all 8 since the pairs are tuned in the same octave); bringing them to pitch. Then, using a small piece of wire, finding where the saddle will need to be.

AcornHouse

Venerated Member

AcornHouse

Venerated Member

And, just using a strip of bloodwood acting as a saddle (no refinement at all) with just my fingertips, Thistle speaks.

That's really clever, Chris. I don't think I've seen anyone do this manually like this before.

AcornHouse

Venerated Member

Nothing new, just not always done.That's really clever, Chris. I don't think I've seen anyone do this manually like this before.

ReevesRd

Senior Member

I've been waiting to hear the Octave Mando "Thistle." Sounds great, Chris!

- Joined

- Feb 11, 2009

- Messages

- 23,073

- Reaction score

- 18,727

- Location

- NJ (The nice part)

- Guild Total

- 112

Gorgeous

AcornHouse

Venerated Member

AcornHouse

Venerated Member

- Joined

- Feb 11, 2009

- Messages

- 23,073

- Reaction score

- 18,727

- Location

- NJ (The nice part)

- Guild Total

- 112

Ahh, SCRAPS: System Comprised of Recycled Aged Past Snippets.

Could I just come to your property and pitch a tent in sight of your shop and come watch? I would, only, knock on your shop door when the window shades were letting light in. I know I am missing a creative trick or three.

Opsimath

Senior Member

Could I just come to your property and pitch a tent in sight of your shop and come watch? I would, only, knock on your shop door when the window shades were letting light in. I know I am missing a creative trick or three.

Bring Fuji apple sparkling water and he'll probably let you in. Bring Temptations MixUps, Catnip Fever, and The Boss will certainly let you in.

AcornHouse

Venerated Member

You may want to hold off on learning from me for a bit. Fitting for an instrument called Thistle, I got properly Bobbie Burns'd today.*

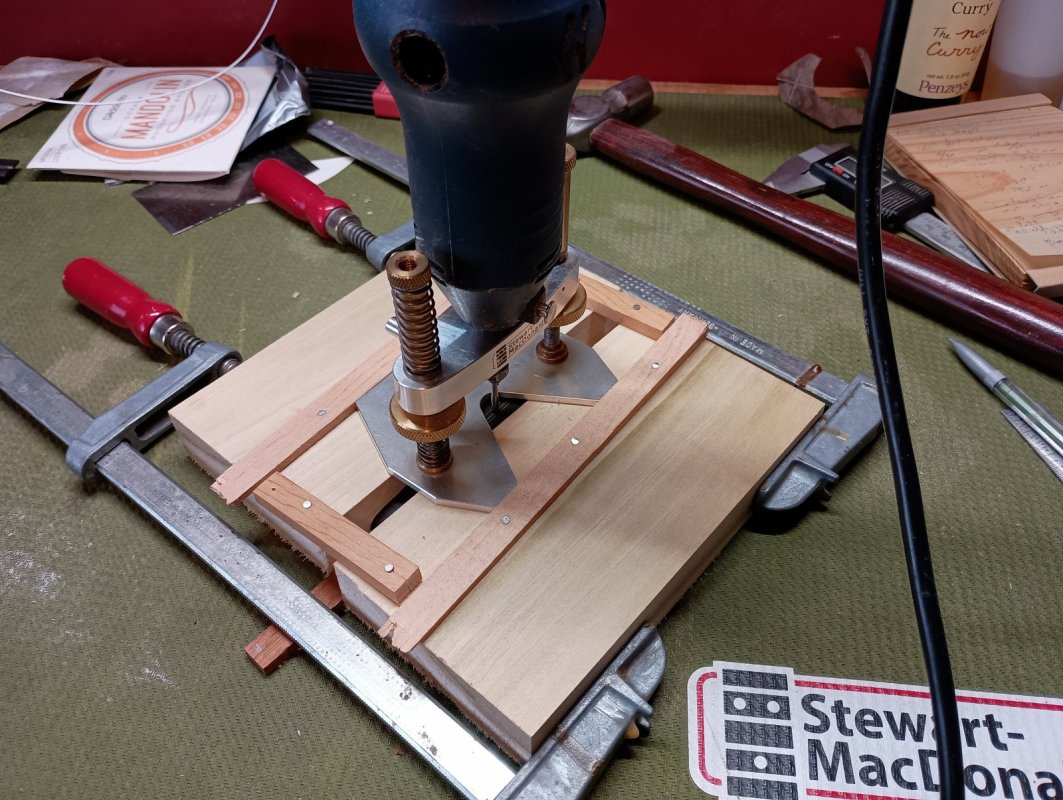

After getting the routing jig all set up, I made my first pass, barely breaking the surface. On the second a little deeper (a little too deeper), I saw one side looking jagged and one end didn't quite seem right. Still not sure if it was operator error or a wandering bit. Continuing down in small increments it seemed to run truer, but after getting to depth, I knew it wasn't right. The top part was ugly and one end was off.

Sigh.

Instrument making is a series of problems needing a solution, and this one was a doozy. Through hard won experience I've learned the best thing to do is to get away from it and do something else. All the while, of course, thinking about how to fix it. Should I try to build up ebony dust and fill the wavy gaps? Should I sister a thin piece and rerout?

Eventually the best solution came to me. Use a wider saddle.

Of course, I didn't have any saddle blanks thicker than 1/8", which is what I'd intended to rout for. But I DID have a nut blank I could use.

The first task was getting a wider, truer, slot for it to fill, and for that I turned to something I could depend on. Chisel, file, and a sanding board. Then I mounted thenut saddle blank in a carrier to send through the drum sander to get it down to thickness. Then cut to length and fine tune the fit.

It's snug, I can lift the bridge up by the saddle safely, but it comes out without forcing.

Whew!

And, for a happy bonus, there's even more roome to intonate.

*"The best-laid schemes of mice and men, Gang aft a-gley."

After getting the routing jig all set up, I made my first pass, barely breaking the surface. On the second a little deeper (a little too deeper), I saw one side looking jagged and one end didn't quite seem right. Still not sure if it was operator error or a wandering bit. Continuing down in small increments it seemed to run truer, but after getting to depth, I knew it wasn't right. The top part was ugly and one end was off.

Sigh.

Instrument making is a series of problems needing a solution, and this one was a doozy. Through hard won experience I've learned the best thing to do is to get away from it and do something else. All the while, of course, thinking about how to fix it. Should I try to build up ebony dust and fill the wavy gaps? Should I sister a thin piece and rerout?

Eventually the best solution came to me. Use a wider saddle.

Of course, I didn't have any saddle blanks thicker than 1/8", which is what I'd intended to rout for. But I DID have a nut blank I could use.

The first task was getting a wider, truer, slot for it to fill, and for that I turned to something I could depend on. Chisel, file, and a sanding board. Then I mounted the

It's snug, I can lift the bridge up by the saddle safely, but it comes out without forcing.

Whew!

And, for a happy bonus, there's even more roome to intonate.

*"The best-laid schemes of mice and men, Gang aft a-gley."

AcornHouse

Venerated Member

Once again - great solution and problem solving skills!